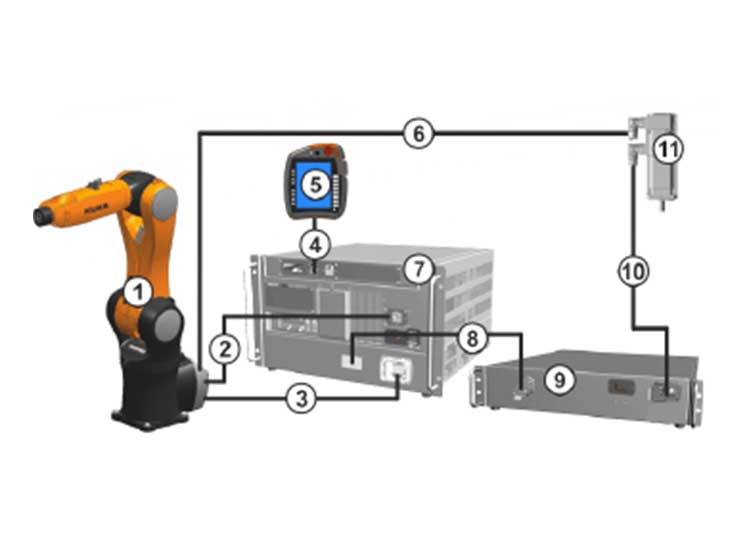

We ensure safety in explosive atmospheres for industries like chemicals, oil & gas, and military, using pressurized enclosure protection (Ex p), flameproof (Ex d), and intrinsic safety (Ex i) techniques.

Modifications involve sealing the robot本体 in a metallic explosion-proof housing, integrating a pressurization control system (maintaining internal pressure > external), and upgrading to explosion-proof connectors, sensors, and electrical cabinets.

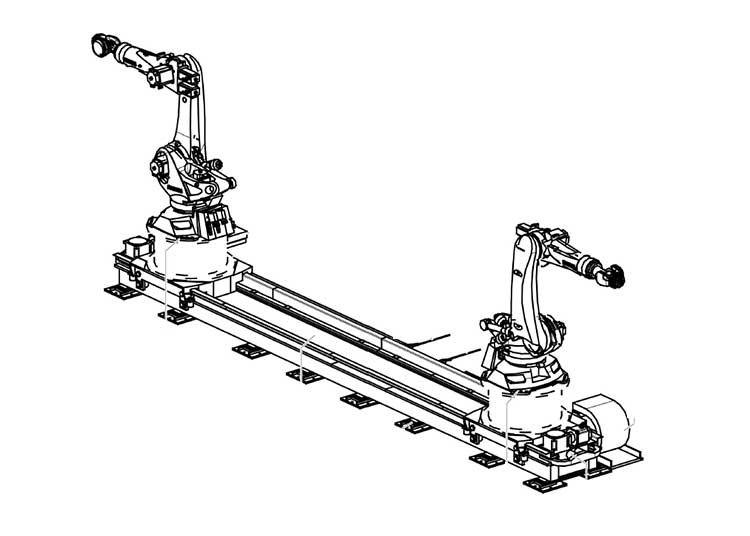

This service adds external servo axes (e.g., rotary tables, positioners, or linear slides) to standard 6-axis robots, enabling 7-axis or even multi-axis coordinated motion.

Through comprehensive system configuration (including synchronized control algorithms and hardware/software interface integration), we ensure precise and coordinated movement between the added axes and the robot.

Application Scenarios: Ideal for processes requiring multi-angle positioning like welding and large workpiece machining, significantly enhancing production flexibility.

This involves installing a robot mobile carriage onto an existing slide rail system, integrated with a drag chain system to protect power cables, air lines, and signal cables.

Post-retrofit, the robot can move along the track to service multiple stations, meeting spatial demands arising from process changes (e.g., new workstations, extended production lines).

Key Advantage: Avoids the cost of purchasing additional robots and remains compatible with the existing equipment base.

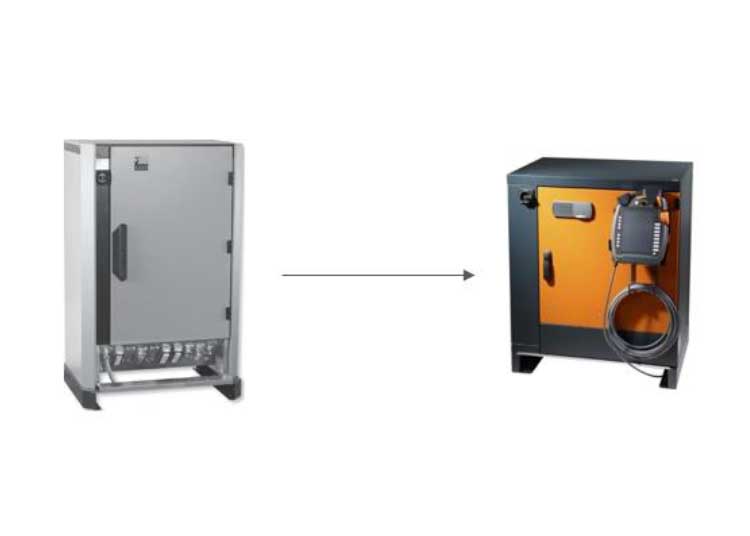

Upgrades older robot control systems to new-generation platforms (e.g., new controller, teach pendant, and software), ensuring continued spare parts availability and technical compatibility.

Eliminates risks from electrical aging (e.g., circuit board, cable failures), reduces unplanned downtime, and unlocks new functionalities (e.g., advanced motion control, IoT connectivity).

Economic Benefit: Extends the service life of existing robots, preventing complete obsolescence due to outdated systems.

Repurposes existing workstations (e.g., converting a spot welding station to material handling) by replacing end-effectors (grippers, welding torches, etc.), adjusting program logic, and re-integrating sensors.

Seamless integration into existing lines: Retains the basic infrastructure (e.g., safety fencing, material flow) while upgrading only the core work unit, minimizing retrofit downtime.

A full-scope service covering equipment disassembly, transportation, installation at the new site, mechanical/electrical reassembly, accuracy recalibration, and program debugging.

Restores the robot to its pre-relocation operational state, ensuring path accuracy and cycle time stability meet original standards. Includes necessary upgrades to protection systems (e.g., cable/pneumatic service packages, grounding systems).

Implements specific protection protocols for precision components (e.g., reducers, encoders) to prevent damage during moving.